- +91- 85916 13086

Company Profile

About Suyash

For the past four decades, Suyash Industries has been at the forefront of addressing corrosion-related challenges through the utilization of FRP composites. Our extensive experience and expertise have solidified our position as industry leaders. We specialize in creating tailored solutions that are specifically designed to combat the individual and distinctive corrosion issues faced by our clients.

Distinguished by customization, each of our solutions is meticulously tailored to address the unique complexities posed by our clients’ specific problems. We understand that no two challenges are alike, and our approach reflects this by crafting bespoke strategies that precisely target the root of the issue.

Central to our success is the utilization of cutting-edge materials such as FRP, GRP, and composite variations with PP, PPH, PVDF, PFA, PVC, PTFE, MS and many more. This diverse array of materials underscores our commitment to crafting solutions that align with the unique demands of each project.

At Suyash Industries, customization is not just an approach – it’s our foundation. We recognize that every corrosion challenge is distinct, necessitating a unique solution. With our decades-long experience, dedication to quality materials, and unwavering commitment to personalized service, we stand poised to offer solutions that not only combat corrosion but also exceed expectations.

Suyash Composite Industries established in the year 1981 under the able leadership of Mr. VK Mundhe

It started off as a one room company and through his tireless efforts, he has taken the company to be one of the leading manufacturers in the field of composites in India.

Quality of the products we manufacture has always been our main focus and we have always insisted on high quality raw material products which are sourced only from certified manufacturers & dealers.

Suyash Industries has manufactured products for a wide range of industries including the power industry, petrochemical, oil and gas, anodizing and galvanizing, dyes and pigments, chemical, pharmaceutical, sugar and many more..

We have had the priviledge of working with blue chip companies like The Tata Electric Co., Hindustan Petroleum Corp. Ltd., Bharat Petroleum Corp. Ltd., B.A.R.C., Bharat Heavy Electrical Ltd., Flackt (I) Ltd., I.P.C.L. and many more companies for the last 44 years.

All our products are manufactured as per the IS / BS4994 / ASTM standards to meet the requirements of the clients.

We design and manufacture chemical process equipment based on FRP composites for handling corrosive chemicals and for preventing corrosion from external factors. We are engaged in carrying out Specialized Anticorrosive Lining based on Advance Reinforced Plastics like glass flake coating for highly abrasive conditions.

Suyash Industries is registered as a MSME with the Ministry of Micro, small and medium enterprises.

Members of

Our Team

We have a dedicated team with varying skillsets who are willing to cater to the needs of our clients. The core of our team is as follows:–

Mr. VK Mundhe

Founder

Has 30 years of vast experience in the field of composite materials.

Completed his B Pharm in 1971 followed with a diploma in business management.

Associated with many leading chemical, petrochemical, power & sugar industries.

Mr. NS Sule

Chemical Engineering graduate from UDCT MUMBAI, and has 22 years of experience in consultancy and manufacturing firms like Parkhe Consultants, Asian Paints, Alta Lab.

He looks after process and mechanical design, scale up and site execution.

Mr. ND Kulkarni

Chemical Engineering graduate from UDCT MUMBAI, and has more than 25 years of experience in leading consultancy and manufacturing firms like Asian Paints etc.

Looks after detailed engineering, procurement & overall project planning & co-ordination.

Mr. Gautam Watve

Chemical engineer and MBA from Mumbai University and a MS in project management in the US.

Used to head the International operations of Shree Renuka Sugars Ltd.

He has 15 years of experience in Strategy, operations, finance and planning functions.

Mr. SR Kulkarni

Chemical Engineering graduate from UDCT MUMBAI and has more than 30 year experience in production department in companies like Gharda chemicals, Aquapharm chemicals.

Looks after detailed engineering and overall project planning.

Mrs. Ashwini Watve

A civil engineer from Mumbai University, she has done various courses conducted by IIT & MCED for moulding in FRP.

Head of the HR department and has 15 years of experience.

Mr. Nilesh Jadhav

He has extensive experience of working in operations of chemical companies. His main expertise is in estimation and execution of projects where he has excelled in implementation of projects successfully.

Mr. PS Pendse

He has wide ranging experience in purchase planning and material handling. His experience as production head of various companies is extremely valuable.

Mr. SS Shinde

He is a site in-charge having past 25 years of experience.

Mr. HV Kumbhar

Having past 20 years’ experience as Site in-charge for specialized jobs.

Our Facilities

Factory

Our factory is centrally located in the Thana-Belapur MIDC at Rabale TTC. This factory is well connected by roads and railway as well. This facility has a 10,000 square feet factory with all the facilities required for FRP moulding & composite fabrication, including two cranes of 20 tons for handling large equipment like tanks, scrubber, ducts & pipelines.

Corporate office

Our office is 2 minutes away from the Mumbai Agra highway (Eastern express highway) in the city of Thane which is one of the suburbs of Mumbai.

Quality Policy

Our company is committed to providing high-quality products and services to our customers. To ensure this, we have developed a comprehensive QA/QC policy that guides our operations and processes and a stringent inspection process for all our products and services.

Our policy includes the following key principles:

- Meeting customer requirements and expectations

- Continuous improvement of our products and services

- Compliance with applicable laws, regulations, and standards

- Effective communication with our customers and stakeholders

- Employee training and development

- Use of appropriate tools and technology to support our processes

- Monitoring and measurement of our performance

Ensuring comprehensive material traceability through meticulous documentation, including Quality Assurance Plans (QAP), detailed Inspection Reports, and the involvement of Third-Party Inspection (TPI) inspectors

We enable TPI inspectors and clients to utilize our calibrated instruments, ensuring the exceptional quality of all our products, which is thoroughly documented in our internal reports ultimately contributing to our pursuit of ISO Certification.

Milestones

1981

Started proprietary company - Suyash Industries by Mr. VK Mundhe

1983

Refurbishment of Sea water pumps using specialized formulations - Import substitution

1985

First shutdown corrosion protection services for Thermal power plants

1987

FRV Lining to FGD - Scrubbing system, ducting and aeration basin

1991

Pioneer is starting FRE lining and Epoxy coating for valves upto 38' diameter

1993

Refurbishment of Condenser tube sheets in Power plants and Refineries

1995

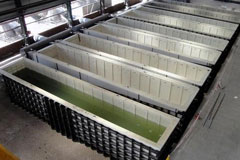

Design and supply of turnkey composite system for Pre-treatment and Anodizing Tanks

1996

First Supply of FRP and FRP Composite reactors, Scrubbings systems and Tanks

1998

Supply of 25m diameter FRP Bio-reactor floating roofs for the Sugar industry

2005

Developed the formulation of Glass Flake coating as a substitute for imported material

2006

High temperature Glass Flake coating for FGD ducts and FGD- GGH

2008

Glass Flake coating for ESPs for Power Plants

2012

Turnkey supply and installation of Tanks, Scrubbing system and piping for a client

2013

First supply of Large composite tanks of 80KL capacity

2016

Designed and manufactured 35Ft Scrubbing system as a replacement for imported scrubbers

2018

First export of corrosion protection contract and supply of equipment

2019

Converted Proprietary company into a limited company - Suyash Composite Industries Pvt. Ltd.

2020

Designed and manufactured critical scrubbing systems for Defense research organization

2021

Internal and External Glass Flake coating for Fire water pipelines

Industries we serve

Anodizing/Galvanizing/Powder Coating Plants

Automobile Industry

Chemical Industry

Civil Industry

Dyes and Pigments

Electrical Industry

Pulp and Paper

Petrochemical and Refineries

Pharmaceutical Industry

Pickling Units

Power Industry

Steel Plants

Sugar Industry

Textile Industry