- +91- 85916 13086

Glass Flake Coating Solutions

Glass Flake Coatings

Glass flake coatings is a type of protective coating that consists of a matrix material, such as epoxy, Vinyl Ester or polyester, reinforced with glass flakes. Glass flakes are thin, flat particles made from glass, typically about 1-5 micrometres thick and 50-500 micrometres wide.

The glass flakes in the coating provide a number of benefits. They act as a barrier to prevent moisture, gases, and other substances from penetrating the coating and reaching the underlying surface. They also increase the coating’s toughness and abrasion resistance, and can help to reduce the coefficient of friction.

Glass flake coatings are used in a variety of applications where protection against corrosion and wear is required. They are also used in the oil and gas industry, chemical industry to protect pipelines and equipment from corrosion and abrasion. They are also used in the marine industry to protect ship hulls and offshore structures from the harsh marine environment.

In addition to their protective properties, glass flake coatings can also provide aesthetic benefits. They are available in a range of colors and finishes, and can be used to create a variety of textures and patterns.

Our Glass Flake coating is FDA-approved

Glass Flake Coating Solutions

Leveraging extensive research and meticulous analysis, we proudly introduce our cutting-edge glass flake coatings: Flakoat E Series, Flakoat P Series and Flakoat V Series. The comprehensive product range within each Flakoat series allows us to provide tailored solutions, addressing specific requirements across various industries and applications. Whether clients demand specialized features, varying degrees of protection, or specific performance characteristics, our Flakoat series offers a versatile array of coatings to meet their diverse needs

The Flakoat series has been extensively applied internally and externally to many equipment like the following –

- Storage Tanks, Reactors, Pressure Vessels,

- Ducts and Pipelines

- Gate Valves, Check Valves and Strainers

- Critical applications like FGD Ducts, FGD Absorbers and GGH in Power Plants,

- Protection of MS Structures

Flakoat E Series, Flakoat P Series and Flakoat V Series are engineered to withstand high temperatures, showcasing remarkable resistance to both corrosion and abrasion. Our commitment to innovation and meeting modern needs is evident in the extensive testing and continuous reformulation of our Flakoat series over the years. This ongoing refinement process ensures that these coatings align seamlessly with contemporary requirements.

Their popularity is a testament to their ability to provide durable and resilient protection, making them preferred choices for industries that prioritize durability, high-temperature resistance, and robust corrosion and abrasion resistance.

Glass Flake Coating Gallery

Solutions

Glass Flake Epoxy: Flakoat E Series

FLAKOAT E – 1100 Glass Flake Epoxy Primer

FLAKOAT E – 1100- Glass flake epoxy primer is a type of coating that consists of small flakes of glass embedded in an epoxy resin. This primer is known for its excellent corrosion resistance and is commonly used in industrial and marine applications.

FLAKOAT E – 1300 Glass Flake Epoxy Coating

FLAKOAT E – 1300 – Glass flake epoxy coating is a type of protective coating that uses a combination of glass flakes and epoxy resin to provide exceptional resistance to corrosion, abrasion, and chemical exposure. This coating is commonly used in harsh environments such and chemical plants.

FLAKOAT E – 1350 Glass Flake Epoxy Coating – Pipes and Fittings

FLAKOAT E – 1350 – Glass flake epoxy coating for pipes is frequently used to protect pipes from corrosion and abrasion, particularly in the oil and gas industry. This coating provides excellent resistance to harsh environments and can extend the service life of pipes.

FLAKOAT E – 1500 Glass Flake Epoxy Coating – High Temperature

FLAKOAT E – 1500 – Glass flake epoxy coatings are designed to withstand high temperatures and are often used in applications where elevated temperatures are present, such as in pipelines carrying hot fluids. These coatings offer excellent resistance to thermal shock and provide long-lasting protection in high-temperature environments.

FLAKOAT E – 1700 Glass Flake High Build Epoxy

FLAKOAT E – 1700 – Glass flake high build epoxy is a type of coating that contains a high concentration of glass flakes and offers superior build-up properties. This coating is often used in applications where high film thickness is required to provide maximum protection against corrosion, abrasion, and chemical exposure.

Glass Flake Vinyl Ester: Flakoat V Series

FLAKOAT V – 2100 Glass Flake Vinyl Ester Primer

FLAKOAT V – 2100 – Glass flake vinyl ester primer is a type of coating that uses a combination of glass flakes and vinyl ester resin to provide excellent resistance to corrosion, abrasion, and chemical exposure. This primer is commonly used in marine and corrosion environment where superior protection is required.

FLAKOAT V – 2300 Glass Flake Vinyl Ester Coating

FLAKOAT V – 2300 – Glass flake vinyl ester coating is a type of high-performance coating that uses a combination of glass flakes and vinyl ester resin to provide superior resistance to corrosion, abrasion, and chemical exposure. This coating is commonly used in harsh environments such as chemical plants, oil and gas refineries, and offshore structures.

FLAKOAT V – 2350 Glass Flake Vinyl Ester Coating – Pipes

FLAKOAT V – 2350 – Glass flake vinyl ester coating is often used to protect pipes from corrosion, abrasion, and chemical exposure in harsh environments such as oil and gas pipelines. This coating provides superior protection and extends the service life of pipes in such conditions.

FLAKOAT V – 2500 Glass Flake Vinyl Ester Coating – Medium Temperature

FLAKOAT V – 2500 – Glass flake vinyl ester coating is a type of coating that can withstand high temperatures and is commonly used in applications where elevated temperatures are present, such as in chemical processing equipment and exhaust systems. This coating provides excellent resistance to thermal shock and offers long-lasting protection in high-temperature environments.

FLAKOAT V – 2700 Glass Flake Novolac Vinyl Ester Coating- High Temperature

FLAKOAT V – 2700 – Glass flake novolac vinyl ester coating is a high-performance coating that contains a combination of glass flakes and novolac vinyl ester resin, providing exceptional resistance to corrosive and abrasive chemicals. This coating is commonly used in aggressive environments such as chemical plants and oil refineries.

FLAKOAT V – 2900 Glass Flake Novolac Vinyl Ester coating – FGD

FLAKOAT V – 2900- Glass flake novolac vinyl ester coating is frequently used in Flue Gas Desulfurization (FGD) systems to protect equipment from the highly corrosive, high temperature and abrasive environment. This coating offers excellent resistance to acidic gases and extends the service life of FGD equipment and Ducts.

Flakoat P - Glass Flake Polyester Series

FLAKOAT P – 3100 Glass Flake Polyester Primer

FLAKOAT P – 3100 – Glass flake polyester Primer- is a specialized coating composed of glass flake particles within an resin matrix. This formulation imparts exceptional corrosion resistance, mechanical strength, and barrier properties to surfaces.

FLAKOAT P – 3300 Glass Flake Polyester Coating

FLAKOAT P – 3300 – Glass flake polyester Coating is a specialized protective layer comprised of glass flake particles embedded within an polyester resin matrix. This coating is engineered to deliver outstanding corrosion resistance, mechanical strength, and barrier properties, making it ideal for challenging environments.

FLAKOAT P – 3350 Glass Flake Polyester Coating – Pipes and Fittings

FLAKOAT P – 3350 – Glass flake polyester Coating – Pipes and Fittings – is a specialized protective solution designed for exceptional durability and corrosion resistance. This coating incorporates glass flake particles within a polyester resin matrix, providing superior mechanical strength and a robust barrier against corrosive elements

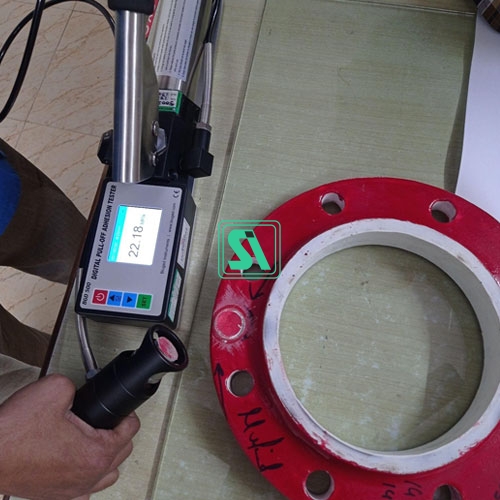

Testing

Testing is a critical phase in our product development, and we take pride in subjecting our brands to rigorous assessments at renowned laboratories, such as UDCT. Our commitment to quality is underscored by surpassing the stringent benchmarks established by EIL India and other reputable standards.

These products undergo repeated and thorough testing, ensuring they consistently meet and exceed the high standards set by our clients. To validate our commitment to quality, Third-Party Inspectors (TPIs) have verified the performance and reliability of our products through independent assessments. This dedication to testing and quality assurance ensures that our brands not only meet regulatory requirements but also deliver exceptional performance and reliability in real-world applications.

Glass Flake Coating Use

Glass flake coatings are commonly used in various industries where protection against corrosion, abrasion, and chemical exposure is essential. Here are some examples of industries where glass flake coatings are used:

Glass flake coatings are frequently used to protect pipes, tanks, and other equipment in the oil and gas industry from corrosion and abrasion.

Glass flake coating have been widely used in the industry due to its excellent resistant properties against abrasion, corrosion and high temperatures.

Glass flake coatings are used in chemical processing plants to protect against chemical exposure and to provide a smooth, easy-to-clean surface.

Glass flake coatings are used in power generation facilities, including coal-fired and gas-fired power plants, to protect against corrosion and abrasion.

Glass flake coatings are used in water treatment facilities to protect equipment against corrosion and to provide a smooth, easy-to-clean surface.

Glass flake coatings are used in the transportation industry, including in the automotive and aerospace industries, to protect against corrosion and to provide a durable, long-lasting finish.

Technical Support & Client Services

Get advice, specialist technical support or info on our dedicated project management service